Navigating Defense Innovation: A Framework for US Industrial Base Revival

Why systematic coordination, not bureaucratic speed, holds the key to military technological supremacy

On a foggy morning in eastern Ukraine, a few hundred dollar Chinese-made quadcopter—purchased on Amazon and modified in a Kyiv garage—destroyed a $4.2 million Russian T-80 tank. The pilot, a 19-year-old Ukrainian who learned to fly drones playing video games, accomplished what decades of advanced weapons development had aimed to achieve: precision elimination of armored targets with minimal cost and risk.

This moment encapsulates the transformation reshaping modern warfare. Commercial technologies, iterated at software speed and deployed by citizen-soldiers, are rewriting military doctrine faster than Pentagon procurement officers can process requisition forms. What defense contractors spent decades perfecting, innovators now achieve in months using off-the-shelf components and 3D printers.

We are, as one defense strategist recently observed, "in the foothills of a cold war." The strategic landscape of 2025 presents multiple simultaneous challenges: escalating tensions with China as it expands influence through 29 Free Trade Agreements compared to America's 20, the persistent Russo-Ukrainian conflict as Moscow strengthens ties with non-Western powers, and emerging technologies that compress the timeline from innovation to battlefield deployment.

The Pace of Innovation

The numbers tell the story of a technology revolution that defense establishments struggle to master. While commercial sectors experience unprecedented growth in critical defense-relevant technologies, traditional military procurement cycles remain trapped in decades-long development timelines.

The strategic implication is profound: Commercial sectors are creating defense-relevant capabilities at speeds that traditional military procurement cannot match. Artificial intelligence capabilities that could revolutionize battlefield decision-making are advancing at 35.9% annually, while defense AI programs average 8-15 year development cycles. The mathematical reality is unforgiving—commercial innovation timelines are now 3-5 times faster than military acquisition processes.

Yet America's defense establishment struggles with a fundamental paradox. Despite spending $842 billion annually on defense—more than the next ten countries combined—the United States cannot rapidly test, procure, and field emerging capabilities within months or weeks. The average time from prototype to deployment remains 8-15 years, while adversaries iterate capabilities in 3-5 year cycles.

The core problem isn't slow procurement—it's systematic fragmentation. Like manufacturers in the 1920s producing lumber in 400 different sizes, today's defense contractors develop systems that can't communicate, share data, or integrate seamlessly. A RAND Corporation study found the Pentagon uses hundreds of different communication systems that cannot share information—the modern equivalent of incompatible screw threads that once plagued American industry.

America has solved this exact problem before. The solution requires understanding why systematic standardization, not bureaucratic acceleration, holds the key to military technological supremacy.

Two Tales of US Defense Innovation Procurement

To understand where we stand today, we must examine how America has approached defense innovation in the past. Two stories illustrate the extremes of American defense procurement—one representing the gold standard, the other a cautionary tale about complexity and ambition.

"The pistol that won two World Wars"

The Colt M1911's development story reads like a masterclass in effective military procurement. For 74 years—from the trenches of World War I to the jungles of Vietnam—it served as America's standard military sidearm, firing over 100 billion rounds in conflicts across six continents.

The origin began with brutal clarity. After the Philippine-American War, U.S. Cavalry Captain John J. Pershing submitted a report that would reshape American military thinking: "The .38 caliber is entirely inadequate. Moro warriors, even when hit five or six times, continue to advance and kill American soldiers who are frantically trying to reload."

The procurement process that followed became textbook acquisition: The Army released public specifications in 1906, six manufacturers submitted designs, transparent testing eliminated four candidates, and a decisive 48-hour evaluation settled the competition. After firing 6,000 rounds, the Colt .45 functioned flawlessly while its competitor suffered 37 malfunctions. When the Colt overheated during testing, evaluators simply immersed it in water—demonstrating the ruggedness that would serve from Belleau Wood to Fallujah.

Total development time: five years. Total cost: $150,000 (roughly $4.5 million today). Service life: 74 years across two world wars, Korea, and Vietnam.

The M1911 succeeded because it embodied five principles: clear operational requirements driven by battlefield experience, transparent competition among proven manufacturers, rigorous field testing under combat conditions, decisive selection within a reasonable timeframe, and elegant engineering focused on solving specific problems rather than every conceivable challenge.

“The plane that ate the Pentagon"

Fast-forward a century, and American defense procurement tells a starkly different story. The F-35 Joint Strike Fighter program represents both the antithesis of efficient procurement and, paradoxically, the eventual delivery of transformational military capability.

As the Berlin Wall fell, Pentagon planners envisioned an elegant solution: create one aircraft to replace aging F-16s, A-10s, F/A-18s, and Harriers across all three services while sharing costs with international partners. The concept embodied post-Cold War optimism about cooperation and efficiency.

The numbers tell the story of ambition meeting reality. The F-35 program now costs $406 billion for development and procurement, with lifetime operating expenses projected at $1.7 trillion over 60 years. The attempt to "solve every problem in attack aviation simultaneously" created unprecedented technical complexity: different variants for three services, international technology-sharing agreements spanning nine countries, and software requirements exceeding 8 million lines of code.

The engineering challenges were legendary: uneven weight distribution requiring constant software compensation, helmet-mounted displays that caused motion sickness, and international disputes over source code access that strained alliance relationships. Canada threatened withdrawal, Australia delayed decisions, and cost overruns triggered congressional investigations.

Yet here emerges the paradox that defines modern defense procurement. Despite these challenges, the F-35 has ultimately delivered transformational capabilities. Over 800 aircraft now operate worldwide, proving combat-effective from Syria to the South China Sea. Unit costs have dropped to $80 million for the F-35A—expensive but approaching original targets. Israeli F-35s have demonstrated stealth effectiveness in contested airspace, and Marine F-35Bs have validated expeditionary operations from forward bases.

The lesson: Advanced capabilities are achievable through current processes, but at costs and timelines that multiply necessary investments by factors of 3-5. The question becomes whether America can develop systematic approaches that capture the M1911's focused efficiency while delivering the F-35's transformational capabilities.

"The Great Standardizer: Setting the Foundation for Modern Day Industrialization"

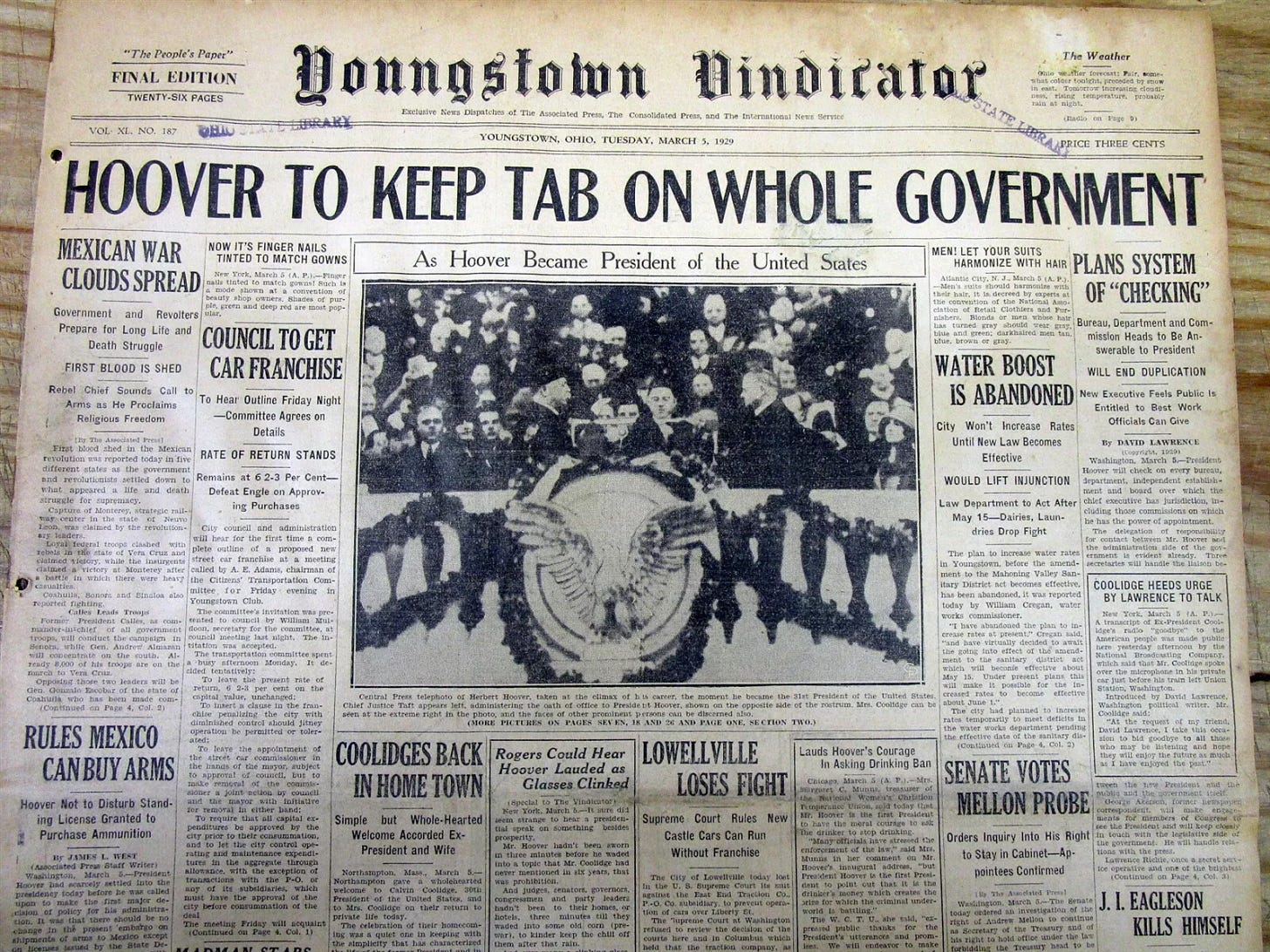

Perhaps no figure better illustrates the power of systematic transformation than Herbert Hoover in his role as "The Great Standardizer." His work in the 1920s offers profound lessons for today's defense industrial challenges—and serves as a blueprint for the kind of systematic reform America needs now.

When Hoover arrived at the Department of Commerce in 1921, American manufacturing embodied chaos. Lumber companies produced boards in over 400 different sizes. Brick manufacturers offered 66 varieties for standard construction. Hardware makers created thousands of different screw thread standards, meaning parts from different companies rarely fit together. The waste was staggering—an estimated 25% of manufacturing costs stemmed from incompatibility and redundancy.

Hoover's systematic solution eliminated waste through coordinated standardization, not protective regulation. Working with industry associations, technical societies, and trade groups, he orchestrated forums where manufacturers voluntarily agreed on common standards. The approach was revolutionary: government facilitated cooperation but didn't mandate compliance.

Five Foundations for the Modern Age:

1. The Lumber Revolution (1922-1924) Working with timber companies, lumber dealers, and construction firms, Hoover reduced lumber sizes from over 400 dimensions to 15 standard specifications. Construction costs dropped 20%, inventory requirements plummeted, and building times accelerated significantly. Home construction costs fell from $6,500 to $4,800 for comparable structures.

2. Hardware Harmonization (1923-1925) Organized forums where screw, bolt, and fitting manufacturers agreed on standard dimensions and threading. For the first time in American industrial history, parts became truly interchangeable across manufacturers. Assembly time for complex machinery dropped 30-40%.

3. Automotive Industry Coordination (1924-1926) Standardized tire specifications, electrical systems, and component dimensions across manufacturers. This coordination enabled the automobile industry's explosion from 1.9 million vehicles annually to 4.3 million by 1929, while creating nationwide parts and service networks.

4. Aviation Foundation (1925-1927) Established uniform aircraft manufacturing protocols, standardized airport design principles, and created systematic navigation aids. These standards enabled commercial aviation's emergence and military aviation's rapid expansion during World War II.

5. Radio Revolution (1926-1928) Organized frequency allocation, established broadcasting standards, and coordinated equipment specifications. These standards created the foundation for America's telecommunications dominance that lasted through the internet age.

The results by 1928 were unprecedented in industrial history:

Manufacturing costs dropped 15-30% across major industries

Industrial productivity grew 4-5% annually throughout the decade

Building materials variety reduced from thousands to hundreds of standard options

Consumer prices fell while wages rose 8% annually

American exports increased 40% as standardized products competed globally

Corporate profits increased 62% while employment rose 14%

Most importantly, standardization created competitive advantage rather than reducing it. American manufacturers didn't become less innovative—they became more efficient at converting innovation into scalable products. Standard interfaces enabled rapid integration of new technologies, while reduced complexity lowered barriers for new entrants.

Today's Defense Industrial Crisis: The Same Challenge, Higher Stakes

Today's defense industrial base faces the identical crisis that plagued 1920s manufacturing. Recent Pentagon assessments reveal systematic fragmentation that would have been familiar to Hoover:

Communication Chaos: Defense contractors difference communication protocols that cannot seamlessly exchange data

Data Format Proliferation: Intelligence systems use different data formats, requiring custom translation for sharing

Interface Multiplication: New weapons systems different interface standards, each requiring custom integration

Security Standard Variation: Cybersecurity compliance requires meeting several different frameworks across services and agencies

The costs mirror 1920s manufacturing waste: A 2024 Government Accountability Office study found that integration challenges add $45-65 billion annually to defense spending—roughly equivalent to the entire annual budget of the Department of Homeland Security.

Recent examples illustrate the practical consequences:

Project Convergence Integration Challenges: The Army's signature modernization effort struggled for 18 months to connect systems from different contractors. Simple data sharing between reconnaissance drones and artillery systems required developing custom software bridges costing $127 million.

Navy Distributed Maritime Operations: Fleet integration exercises revealed that ships from different procurement eras cannot share targeting data without manual radio relays, reducing response times from minutes to hours.

Air Force Advanced Battle Management System: Connecting F-35s, F-22s, and legacy aircraft required developing 47 different interface protocols, delaying deployment by 30 months and adding $890 million to program costs.

The pattern is clear: like Hoover's incompatible screw threads, defense contractors develop proprietary systems that resist integration, multiplying costs and reducing effectiveness.

Enter the Defense Innovation Holy Trinity

Despite recognition of these challenges, America has built significant innovation infrastructure attempting to bridge the notorious "Valley of Death" between promising prototypes and deployable capabilities. This metaphorical valley represents where breakthrough technologies die—not from technical failure, but from procurement system inadequacies that fail to match the speed of innovation development.

The reality is more painful than the metaphor suggests. Dual-use founders consistently express frustration with what industry insiders call "pilot purgatory"—endless cycles of pilots, demonstrations, and studies without clear, actionable, or timely paths to meaningful revenue or formal Programs of Record. Many companies cease pursuing DoD work entirely, finding more traction in commercial markets where decision cycles align with business realities.

The Reality Check: Structural Misalignment

Yet despite this infrastructure and accelerating global competition, fundamental gaps persist that reveal a deeper structural problem:

Mission-Focused vs. Requirements-Driven Misalignment: Founders and investors point to a critical structural issue—acquisition cycles that prioritize legacy requirements instead of real-time mission needs. This creates a dangerous lag between what's technically possible and what actually gets funded. We're trying to solve 21st-century security problems with a mid-20th-century acquisition model.

Mission-focused approaches—those built around operational outcomes rather than predetermined specifications—offer a more adaptive path. But many program offices still lack the structural incentives or authority to adopt them at scale. The result is a system that rewards compliance with outdated requirements over innovative solutions to current threats.

The Numbers Tell the Story:

Timeline Reality: Average development time remains 8-15 years from concept to deployment, while China demonstrates 3-5 year cycles and commercial technology companies iterate in 6-18 month periods.

Scale Challenges: Only 3% of defense spending flows to nontraditional vendors, despite representing 67% of relevant innovation capacity according to Defense Innovation Board assessments.

Integration Failures: Success rate for transitioning prototypes to production programs remains below 23%, with most failures attributed to integration complexity rather than technical performance.

Clearance Bottlenecks: Security clearance processing averages 18 months for nontraditional vendors, effectively eliminating startups from consideration for classified programs.

The innovation infrastructure exists, but systematic fragmentation prevents effective scaling.

"We are in the foothills of a cold war."

While America debates incremental reforms, China implements systematic coordination that would have impressed Herbert Hoover. Intelligence assessments reveal a defense innovation enterprise built on standardization principles:

Unified Technical Standards: China's defense industrial base operates on standardized technical interfaces mandated across all contractors. New systems must demonstrate compatibility with existing platforms before receiving production contracts.

Integrated Civil-Military Development: Commercial technology companies like Baidu, Tencent, and ByteDance develop dual-use capabilities through standardized government interfaces. Military applications emerge from commercial platforms rather than separate development tracks.

Coordinated Procurement Cycles: Defense procurement operates on synchronized 3-year cycles aligned with commercial technology refresh rates. This coordination enables rapid integration of emerging capabilities.

Systematic Testing Infrastructure: Standardized testing protocols allow capabilities developed by different organizations to be evaluated and integrated rapidly. Testing data from one program automatically applies to similar systems.

The results speak for themselves: China's defense capabilities have advanced from peer competitor status to near-peer across multiple domains in under two decades. Hypersonic weapons, integrated air defense systems, and anti-ship ballistic missiles demonstrate the effectiveness of systematic coordination.

Most concerning for American planners: China's approach enables rapid scaling of successful prototypes. While American systems remain trapped in integration challenges, Chinese capabilities move from demonstration to deployment in timeframes that would have been impossible under traditional approaches.

Scaling Nontraditional Defense: Six Pillars of Defense Standardization

The Defense Innovation Board's recent report, "Scaling Nontraditional Defense Innovation," offers more than incremental reforms—it presents a systematic overhaul comparable to Hoover's 1920s transformation. Rather than bureaucratic tweaks, these six reform areas represent fundamental changes to how America develops and deploys defense capabilities.

First, focused organizational structure. The current acquisition landscape resembles pre-Hoover manufacturing chaos—fragmented and difficult to navigate. The solution: expand DIU as a cross-service "Sherpa" with AI-powered market research tools, staffed by independent acquisition experts empowered to identify and procure emerging commercial solutions rapidly.

Centralized Market Intelligence: Database tracking 50,000+ defense-relevant companies globally, updated through automated data collection and machine learning analysis

Standardized Evaluation Protocols: Common assessment criteria for commercial technologies across all services, reducing duplicated evaluations

Unified Procurement Authority: Streamlined decision-making for acquisitions under $25 million, eliminating redundant reviews and approvals

Cross-Service Integration: Mandatory coordination requirements ensuring new capabilities work across service boundaries

Second, cultural optimization. Like Hoover's forums that brought manufacturers together, the DoD must train acquisition officers in relational contracting, emphasizing communication and empathy over bureaucratic compliance. This means streamlining solicitation processes, eliminating redundant reviews, and developing separate tracks for traditional and nontraditional vendors.

Innovation Partnership Curriculum: 120-hour certification program teaching acquisition officers to work with nontraditional vendors

Rapid Prototyping Protocols: Standardized 90-day evaluation cycles for proven commercial technologies

Failure Tolerance Metrics: Performance measurements rewarding calculated risks and rapid learning rather than perfect execution

Cross-Industry Exchange: Rotation programs placing acquisition officers in commercial technology companies

Third, dedicated capital mechanisms. Despite increasing private investment, nontraditional vendors struggle transitioning prototypes to production. The solution involves reauthorizing SBIR/STTR programs with reforms to increase Phase III transition rates, launching a Rapid Integrated Scalable Enterprise (RISE) program, and creating an "Oasis Fund" for high-potential dual-use technologies.

Enhanced SBIR/STTR Programs: Increase Phase III transition rates from 12% to 35% through standardized progression criteria and dedicated transition funding

Rapid Integrated Scalable Enterprise (RISE) Program: $2 billion fund for scaling dual-use technologies, with standardized application processes and evaluation timelines

Critical Technology Oasis Fund: $500 million emergency fund for addressing sudden capability gaps, with 30-day response requirements

Production Readiness Investment: Coordinated funding for manufacturing scale-up, including supply chain development and quality assurance systems

Fourth, security clearance reform. Current delays significantly barrier nontraditional vendors' access to classified projects. Centralizing clearance processing under DCSA, implementing coworking-style SCIF infrastructure, and tailoring requirements for small businesses can dramatically reduce barriers to entry.

Streamlined Processing: Reduce clearance timelines to 90 days through centralized coordination under the Defense Counterintelligence and Security Agency

Tiered Security Architecture: Create standardized security levels matching actual program requirements rather than maximum possible classification

Shared SCIF Infrastructure: Establish coworking-style secure facilities in major innovation centers, reducing facility costs for small companies

Reciprocal Recognition: Standardized clearance requirements accepted across all agencies and contractors, eliminating duplicate investigations

Fifth, risk management transformation. Moving from prescriptive, ex-ante assessments to risk-based, ex-post management would allow vendors to comply once and sell to multiple customers. This includes streamlining Authority to Operate processes, implementing continuous approaches using commercial tools, and waiving redundant requirements for already-compliant vendors.

Unified Cybersecurity Standards: Single framework meeting requirements across all services and agencies, with centralized certification valid for multiple programs

Continuous Authority to Operate: Ongoing security monitoring using commercial tools rather than periodic recertification, reducing compliance burden by 60%

Standardized Testing Protocols: Common evaluation criteria for reliability, performance, and security, with results transferable across programs

Risk-Based Assessment: Replace prescriptive checklists with outcome-focused evaluation, enabling innovation while maintaining security

Sixth, supply chain management overhaul. Developing centralized DoD-wide supply chain risk management, mandating supplier transparency for critical programs, and introducing incentives for open standards can reduce proprietary dependencies while maintaining security.

Open Interface Requirements: New systems must use standardized, published interfaces enabling competition for components and services

Coordinated Risk Assessment: Centralized supply chain evaluation eliminating duplicate security reviews while improving threat detection

Supplier Transparency Mandates: Requirements for detailed supply chain disclosure on programs exceeding $100 million, with standardized reporting formats

Alternative Source Development: Systematic programs ensuring multiple suppliers for critical components, reducing single-point-of-failure risks

"History Sets Precedence"

Systematic Reform or Strategic Decline

America faces a fundamental choice between systematic transformation and gradual strategic decline. Current approaches, despite enormous investment, cannot match the development timelines that adversaries achieve through coordination and systematic standardization.

The mathematics are unforgiving: If China maintains 3-5 year development cycles while America requires 8-15 years, technological advantages will systematically erode regardless of spending levels or innovation quality. Time advantages compound, creating cumulative effects that pure spending cannot overcome.

Historical precedent provides clear guidance: Nations that embrace systematic coordination rather than protective isolation create competitive advantages that last decades. Hoover's standardization efforts enabled American industrial dominance from the 1920s through the 1960s. Today's challenges require similar systematic thinking applied to defense innovation.

The stakes extend beyond military capabilities: Systematic defense innovation coordination creates spillover effects that strengthen entire technological ecosystems. Standardized interfaces enable civilian applications, trained personnel transfer capabilities to commercial sectors, and coordinated research creates knowledge bases benefiting multiple industries.

The Hoover Effect

Herbert Hoover understood a fundamental truth that America must remember: systematic standardization creates competitive advantages, not limitations. His coordinated approach to industrial organization enabled American economic dominance that lasted generations. The Colt M1911 demonstrated that clear requirements and systematic evaluation create capabilities with lasting effectiveness. Even the troubled F-35 program ultimately delivered transformational results through persistent systematic development.

Today's challenges demand similar systematic thinking applied with greater urgency. The Defense Innovation Board's recommendations aren't bureaucratic modifications—they represent fundamental transformation enabling America to restore innovation advantages through coordination rather than competition avoidance.

The six pillars of defense standardization offer a comprehensive approach:

Unified organizational architecture eliminating redundant processes

Cultural transformation through standardized innovation training

Coordinated capital mechanisms bridging the Valley of Death

Security clearance standardization removing artificial barriers

Risk management revolution through "comply once, sell everywhere" approaches

Supply chain coordination mandating open standards and alternative sources

Implementation requires systematic commitment over 5-year timelines with measurable milestones and adequate funding. The $8.3 billion investment over five years represents less than 1% of current defense spending while potentially generating $15-25 billion in annual savings through improved efficiency.

Most importantly, systematic standardization enables rapid response to emerging threats rather than constraining innovation. Standard interfaces accelerate integration of new capabilities, coordinated processes enable faster decision-making, and unified evaluation criteria reduce time from prototype to deployment.

The geopolitical imperative is clear: China's systematic coordination enables defense capability development at speeds traditional American procurement cannot match. Russian innovation despite sanctions demonstrates that systematic approaches overcome resource limitations. Global competition in defense technology intensifies daily, with systematic coordination providing competitive advantages regardless of spending levels.

America must choose: embrace systematic reform now, or accept gradual strategic decline through fragmentation and delay. Historical precedent demonstrates that systematic coordination creates lasting competitive advantages. Current examples prove the approach works when properly implemented. The blueprint exists through Defense Innovation Board recommendations.

The question isn't whether transformation is possible—it's whether we have the institutional courage to implement the changes that history shows are necessary.

The time for incremental reform has passed. America needs systematic standardization of its defense innovation enterprise applied with the same systematic thinking that created industrial dominance in the 1920s.

We must remember that periods of great challenge often precede periods of great achievement. The key lies in learning from both our successes and failures, maintaining our commitment to innovation, and systematically building the capabilities needed for an uncertain future.